Evaporative Deposition

Evaporative deposition is a manufacturing process that involves the deposition of a thin film of material onto a substrate by vaporizing a source material and allowing the vapor to condense onto the substrate. This process is commonly used to create thin film coatings or layers of materials that have specific properties or functions, such as insulation, conductivity, or wear resistance.

Evaporative Deposition Applications Includes:

Anti-reflective coatings for optical lenses and displays

Enhance optical clarity and reduce glare on lenses and displays with anti-reflective coatings.

Barrier coatings for flexible packaging materials

Extend shelf life and protect against moisture by applying barrier coatings on flexible packaging materials.

Conductive coatings for flexible electronics and sensors

Enable the production of flexible electronics and sensors with conductive coatings.

Decorative coatings for architectural glass and automotive trims

Add aesthetic appeal to architectural glass and automotive trims using decorative coatings.

Scratch-resistant coatings for various substrates

Increase durability and protect various substrates with scratch-resistant coatings.

Moisture and corrosion protection for electronic components

Provide moisture and corrosion protection for electronic components in challenging environments.

Improve imaging and spectroscopy accuracy with precise optical filters.

Photovoltaic devices for solar energy applications

Harness solar energy efficiently with photovoltaic devices for sustainable power generation.

Wear-resistant coatings for cutting tools and molds

Enhance the lifespan and performance of cutting tools and molds with wear-resistant coatings.

Biomedical coatings for medical devices and implants

Enhance the lifespan and performance of cutting tools and molds with wear-resistant coatings.

Whether you Contact us for customized thin film coatings that drive innovation and performance.

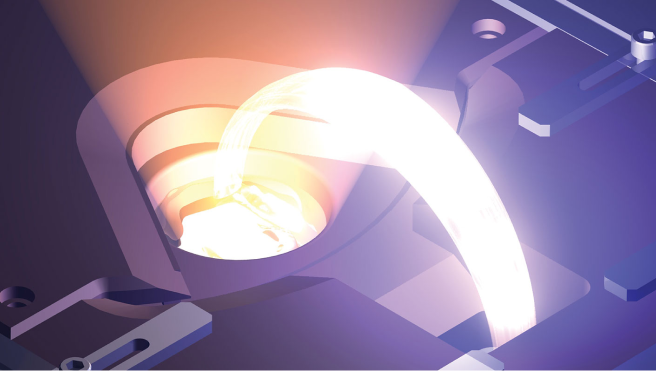

Electron-Beam Deposition

Evaporative deposition offers a versatile range of applications in various industries. Anti-reflective coatings improve the clarity and reduce glare on optical lenses and displays. Barrier coatings protect flexible packaging materials from moisture, extending shelf life. Conductive coatings enable the production of flexible electronics and sensors.

Electron-Beam Deposition Applications:

Optical filters for spectral analysis and imaging devices

Enhance your devices with optical filters for precise spectral analysis and imaging applications.

Optical filters for spectral analysis and imaging devices

Power your microelectronic components with our electron-beam deposition technology for transistors and capacitors.

Thin film coatings for integrated circuits (ICs)

Achieve superior performance with thin film coatings for integrated circuits (ICs).

Transparent conductive coatings for touch panels and displays

Achieve superior performance with thin film coatings for integrated circuits (ICs).

Microelectromechanical systems (MEMS) devices

Explore the possibilities of microelectromechanical systems (MEMS) devices with our advanced deposition techniques.

Electron beam lithography for nanoscale patterning

Drive innovation with nanoscale patterning using electron beam lithography.

Biomedical coatings for implants and medical devices

Ensure safety and reliability with biomedical coatings for implants and medical devices.

Enable high-speed communication with optical waveguides for fiber optic applications.

Optical waveguides for fiber optic communication

Boost the efficiency of solar cells and photovoltaics with antireflection coatings.

High-precision optical coatings for lasers and optics

Unleash the full potential of lasers and optics with high-precision optical coatings.

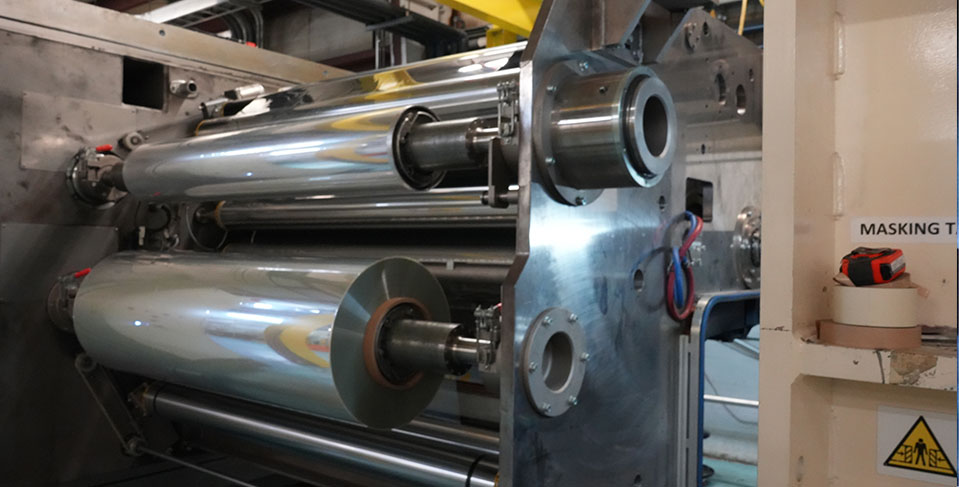

Sputtered Deposition

Evaporative deposition offers a versatile range of applications in various industries. Anti-reflective coatings improve the clarity and reduce glare on optical lenses and displays. Barrier coatings protect flexible packaging materials from moisture, extending shelf life. Conductive coatings enable the production of flexible electronics and sensors.

Sputtered Deposition Applications Includes:

Transparent conductive coatings for touchscreens and displays

Enhance the functionality of touchscreens and displays with our transparent conductive coatings, enabling precise and responsive interactions.

Thin film solar cells for renewable energy generation

Harness the power of renewable energy with thin film solar cells, providing efficient and sustainable electricity generation.

Optical coatings for mirrors, lenses, and filters

Optimize optical performance with our high-quality coatings for mirrors, lenses, and filters, ensuring clarity and precision.

Wear-resistant coatings for cutting tools and machine components

Increase the durability and lifespan of cutting tools and machine components with our wear-resistant coatings, improving performance and reducing maintenance.

Decorative coatings for jewelry and automotive trims

Increase the durability and lifespan of cutting tools and machine components with our wear-resistant coatings, improving performance and reducing maintenance.

Store and access data reliably with our electron-beam deposited magnetic storage media for hard drives.

Gas barrier coatings for flexible packaging

Preserve the freshness and quality of products with our gas barrier coatings for flexible packaging, extending shelf life and protecting against moisture and oxygen.

Hard coatings for optical and ophthalmic lenses

Achieve durability and scratch resistance for optical and ophthalmic lenses with our hard coatings, ensuring long-lasting clarity and vision correction.

Superconducting films for scientific research

Advance scientific research with superconducting films deposited by electron-beam, enabling groundbreaking experiments and discoveries.

Corrosion-resistant coatings for metal substrates

Safeguard metal substrates from corrosion with our corrosion-resistant coatings, providing long-lasting protection in harsh environments.

Unlock the potential of advanced coatings for your applications. Contact us today to explore our diverse range of capabilities.

News & Articles

Latest Blog Posts

What is ITO Sputter Deposition

Indium Oxide/Tin Oxide is among one of the most heavily utilized compounds in the thin film industry due to its electrical conductivity and optical transparency.

Learn more

Vacuum Deposition: A Guide to Thin Film Coating Techniques

One common method for producing thin films is evaporative deposition, which involves the vaporization and subsequent

Learn more

VDI’s Product Development Engineer Receives Technical Award at AIMCAL R2R Conference 2019

Rob Malay, Ph.D., Product Development Engineer at VDI, was the recipient of the John Matteucci Technical Excellence Award at this year’s AIMCAL R2R Conference 2019.

Learn more

VDI Product Development Manager highlights manufacturing advances

Robert Malay, Ph.D., Product Development Manager at VDI, recently co-authored an article for Converting Quarterly entitled “Establishing the flexible-glass R2R coating ecosystem.”

Learn more

VDI Invests in New Equipment, Increases Capacity

VDI today announces a significant investment in new equipment for improved manufacturing with the purchase of a new, world-class vacuum metallizer.

Learn more

Lintec (LUSA) acquires Vacuum Depositing, Inc.

Lintec USA Holding, Inc., a subsidiary of Lintec Corporation, announced today that it has entered into a definitive agreement to acquire Vacuum Depositing, Inc...

Learn more

Ready to Take the Next Step

Ready to explore how VDI's cutting-edge vacuum coating solutions can elevate your products and applications? Contact us today for a free consultation with our experts.

Get a Free Consultation